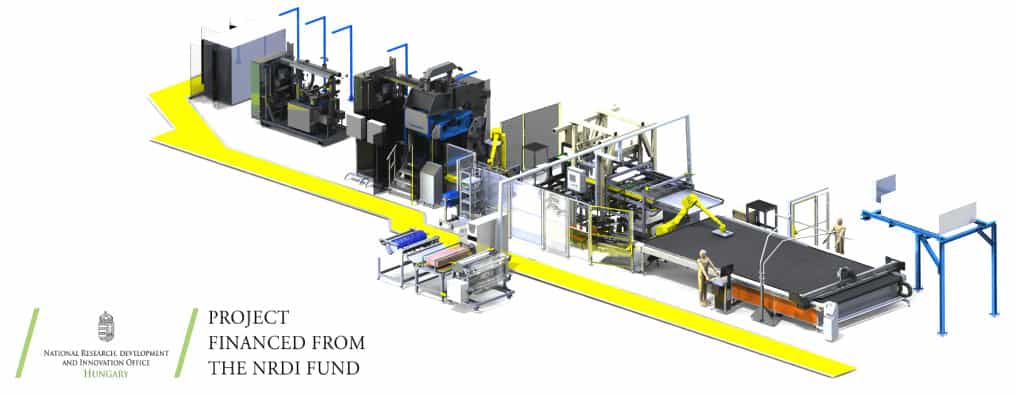

Our recently running large scale development program is targeting the automated, short cycle production of polymer composites, with special focus on the complexity and recyclability of composite elements.

We believe that the thermoplastic composites will have a great potential in automotive industry, because of their superb mechanical properties, versatility, fast producibility and recyclability.

We have three consortium partners in this R&D project: the Department of Polymer Engineering of the Budapest University of Technology and Economics, Research Centre for Natural Sciences of Hungarian Academy of Sciences and eCon Engineering Ltd.

The objective of the project is to develop complex composite parts with near class ‘A’ surface. It is aiming to integrate more functions including continuous fiber reinforcement, stiffness enhancing foam core, reinforcing ribs and metallic inserts. Our goal is to produce recyclable structural composites based on PA6 thermoplastic polymer in mass production with short cycle time for high series automotive applications.

Our design of the manufacturing line is determined by the principles of Industry 4.0. Accordingly, we are aiming to map the quality critical parameters and details of the final product including mechanical properties in order to replace metallic elements used by automotive industry.

HD Composite is leading the program as a consortium leader. The time frame of project is 42 months, and will end in May 2020.

(National ID code: NVKP_16-1-2016-0046)